Driveshafts and parts for all types of commercial vehicles

repair and balancing

Go lower

We guarantee the highest quality at a relatively low production cost for new shafts, repairs, or balancing. We manufacture drive shafts for all types of passenger vehicles, trucks, buses, military vehicles, industrial machines, construction machinery, mining vehicles, metallurgical equipment, and specialized vehicles (fire trucks, etc.).

We also design custom drive shafts according to customer's desired pattern and technical specifications. With our wide range of original and replacement parts, we fulfill orders in a short turnaround time.

We have developed specialized drive shafts tailored to various work conditions, rotational speeds, torque ranges from 200 Nm to 35000 Nm, angle of deflection, and working environments for drive shafts.

Precise balancing of the drive shaft is crucial in terms of safe, reliable, and quiet operation. It also prevents costly repairs to the shaft in the future. Eliminating dangerous vibrations and avoiding premature damage to bearings and supports, and as a consequence, damage to the entire drive shaft. Poor balancing significantly accelerates the occurrence and deepening of damages under high dynamic loads. Importantly, large imbalances can also be dangerous for vehicle drivers and machine operators. Balancing allows for the restoration of the original properties of the shaft.

The balancing process is preceded by a comprehensive diagnosis and elimination of any additional faults. The service of balancing the drive shaft includes balancing the centrifugal forces generated during rotational motion (summing to zero), reduction of mass distribution, and examination of symmetry. Finally, the shaft undergoes meticulous inspection. The entire work is performed by experienced and certified specialists.

We assure that every driveshaft repaired by us is restored to its original condition, including its spline, grooves, welded integrity, alignment, and dynamic balance. The regeneration of driveshafts begins with meticulous diagnosis of damages, such as cracks and wear marks (wear of pivot pins, wear of spline grooves, wear and damage to threads), checking the tolerance of wear in the splined joint, wear of universal joints, any clearances, and other issues that may cause improper operation. We also perform extended diagnostics using specialized machinery when the cause of resonance cannot be found using basic diagnostic procedures.

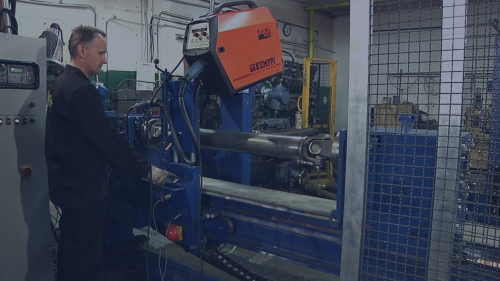

The regeneration of driveshafts is carried out on technologically advanced machines, often using proprietary and innovative solutions in the industry. The process of driveshaft regeneration is automated to achieve the highest level of quality and repeatability. We also conduct periodic inspections and preventive checks. These allow us to identify problems and weak points that may cause major damages to the driveshaft in the near future. This helps to avoid downtime on production lines and costly breakdowns.

We have modern machines tailored to the most advanced digital production technologies. We are the only ones in Poland who produce all drive shafts using the innovative RS7 method (joint pressing into the tube, centering, welding and straightening, balancing, and welding on one machine). The entire repair or production process follows procedures that guarantee craftsmanship.

As a manufacturer of drive shafts and parts, we stand out for our flexibility and efficiency. We are capable of quickly taking on even the most unusual and complicated orders.

What sets us apart is our own production line with a machine park that operates on many innovative technical solutions. Additionally, we work with components from other manufacturers such as Dana - Spicer, Tirsan, Elbe, Klein, and many others.

Discover our wide range of products available immediately.

Propeller shafts for trucks, vans, buses, construction machinery, agricultural machinery, production lines, and fire protection units.

We offer, among others:

We also offer propeller shafts for main, front, intermediate, hydraulic pump, and power take-off applications in the forestry, agricultural, trailer, combine harvester, excavator, loader, crane, metallurgical, iron and steel, paper, food, and automotive industries.

Our production facility can manufacture any custom propeller shaft on customer request. Contact us to learn more about the details.

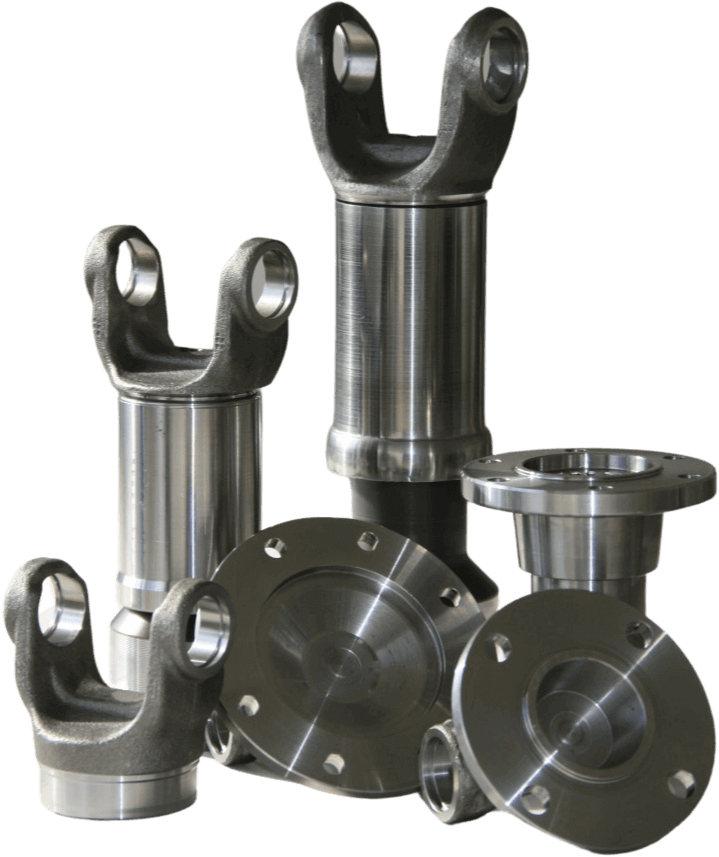

We have parts for propeller shafts from our own production as well as from major foreign manufacturers. We offer original components from leading global companies such as SPICER, GWB. However, what sets our offer apart is our own production line with an advanced machinery park that works on many innovative technical solutions.

We offer, among others: cross joints, bearings, sliding and intermediate joint phrases, crown nuts, shaft housings, forgings, and covers. Contact us and order what you need at a competitive price.

Top-class original supports for trucks, cars, construction machinery, and agricultural machinery.

Supports available for retail sale as well as for wholesale customers. In addition to original supports for all types of driveshafts, we also have our own production alternatives.

High vibration reduction and prevention of rapid wear of the driveshaft.

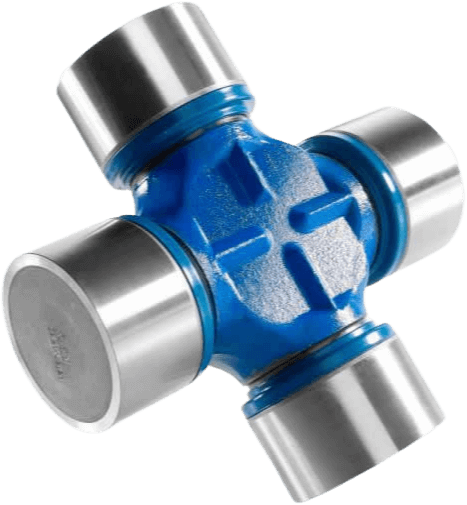

We offer nearly 1000 types of universal joints from leading manufacturers and our own production - available for retail sale and wholesale customers. We supply workshops, garages, and many companies in Europe involved in the production of driveshafts.

Cross joints / universal joints for propeller shafts: mechanical, Heavy Duty, for steering system with hard cup without lubrication or with soft cup, swaged.

|

Zadzwoń do nas: |

|

E-mail: |

|

ul. Kręta 5 87-100 Toruń |

|

NIP: 9581712473 |

|

Zadzwoń do nas: |

|

E-mail: |

|

Świętego Mikołaja 59A 81-062 Gdynia |

|

NIP: 9581712473 |

|

Zadzwoń do nas: |

|

E-mail: |

|

Komunalna 5 83-000 Pruszcz Gdański |

|

NIP: 9581712473 |

|

Zadzwoń do nas: |

|

E-mail: |

|

Plac Konstytucji 3 Maja 2-4 66-234 Boczów |

|

NIP: 9581712473 |

|

Zadzwoń do nas: |

|

E-mail: |

|

Smoleńska 124 85-871 Bydgoszcz |

|

NIP: 9581712473 |